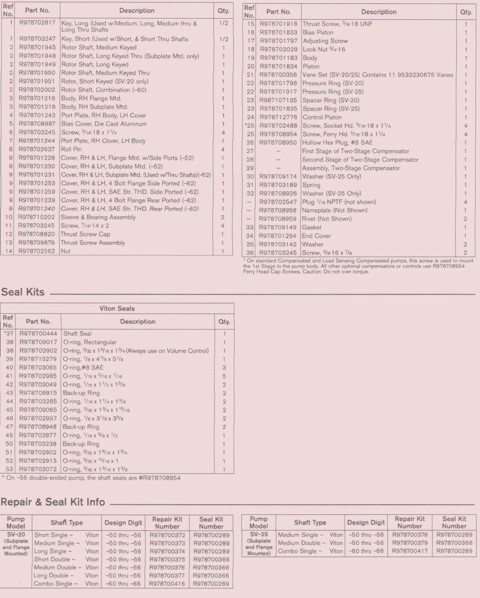

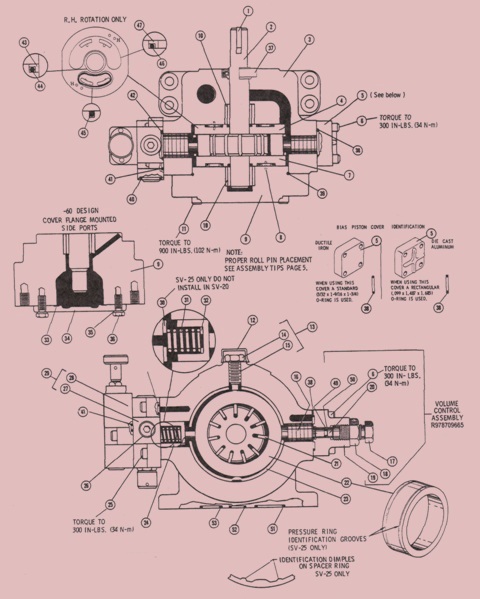

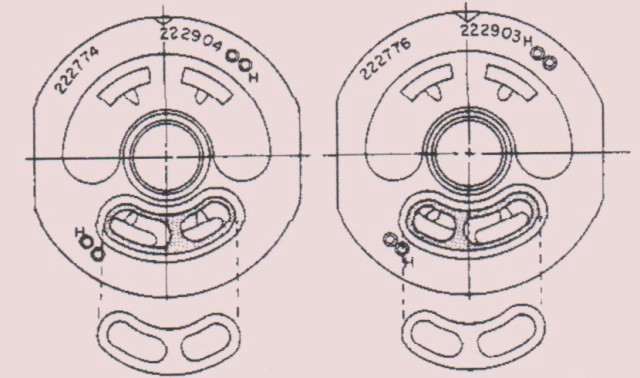

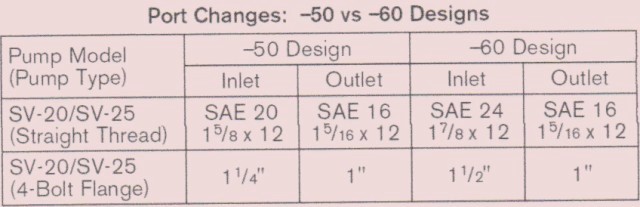

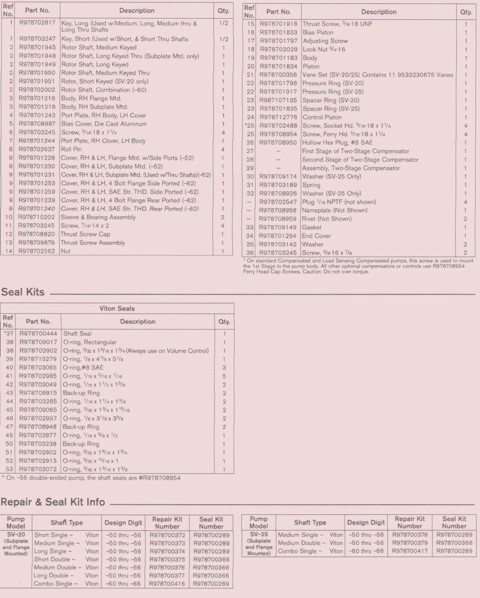

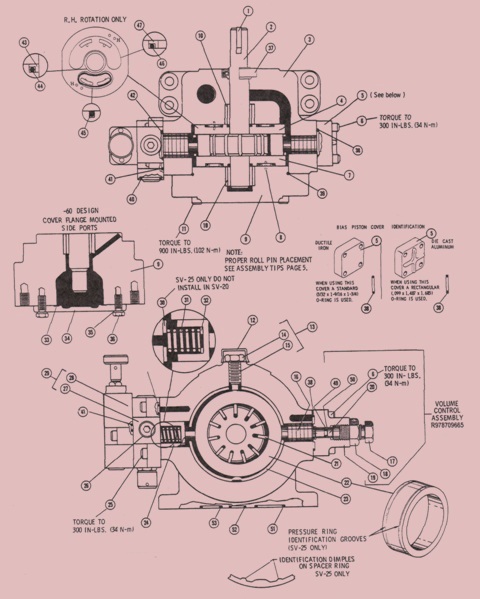

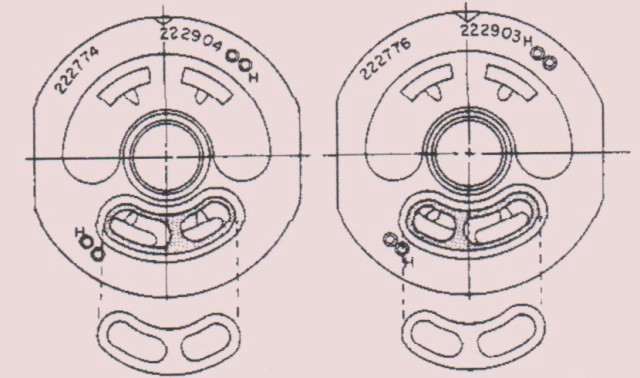

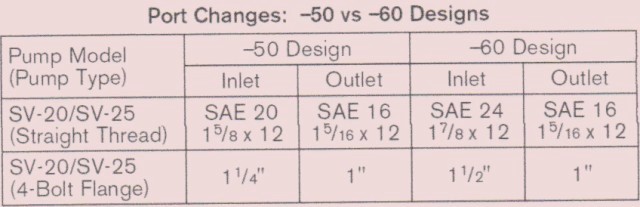

Here are some charts, diagrams and breakdowns that will help you on this particular pump. This is a variable Volume Vane Pump.

Call us at 662-871-8403 or email us at sales@tupelohydraulics.com for more help on this unit

Here are some charts, diagrams and breakdowns that will help you on this particular pump. This is a variable Volume Vane Pump.

Call us at 662-871-8403 or email us at sales@tupelohydraulics.com for more help on this unit