When putting this together have the unit’s shaft in a level position and the valve block mounting is facing up. Turn the shaft til the keyway in the auxiliary shaft til you get to 12:00 position.

This shows being assembled for a RH rotation. Put in the dowel pin in the hole in the port block at a 9:00 position, when you are seeing it from the port block end of the pump. If you are doing a LH, look at from the opposite on the clock 3:00. Next put in the side plate, steel side first and goes over the gerotor assy. on the shaft and be sure to go over the key. Put in the eccentric ring on the dowel pin and the bigger outer gear of the gerotor assy that is inside the eccentric ring and over the inner gear.

Push the needle bearing into the gerotor side plate where the mark is on the end of the bearing right up next to the pressing tool. The marked end needs to be .010 degrees to .025 degrees under the small diameter face of the side plate.

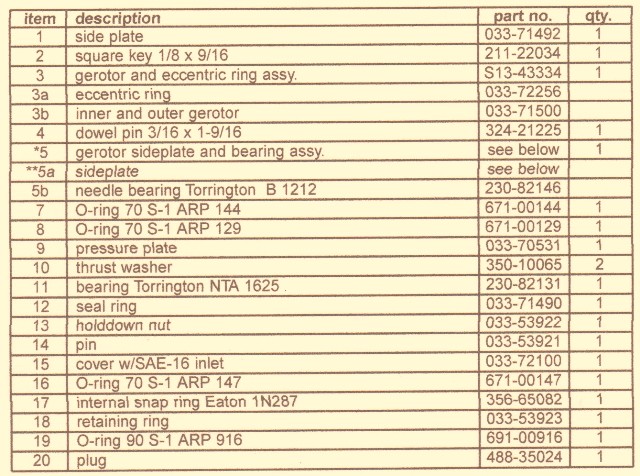

If you need to change your pump rotation, make sure you look at the parts list for the correct side plate.

Put the orings on the side plate assy. Grease the orings and put the pressure plate over the orings on the side plate assy. Put the two plates over the auxiliary shaft and place thethrust gerotor side plate over the dowel pin. Next put the seal ring on the auxiliary shaft. Put the bearing in between the two thrust washers and put it around the seal ring. There is a thread holddown nut on the shaft and tighten it up about 10ft lb pressure. Don’t tighten the nut til the second slot is position correctly with the pin hole in the shaft. Put the pin thru the nut and shaft and put ring on.

Make sure the main shaft has good rotation on it. If it is not, the gerotor and holddown, may need checking again.

Lastly put the oring on end cover and grease it up. Put the end cover that goes over the holddown nut. Let off on the end cover and put in the snap ring. And make sure it is right in the groove. Put the oring on the plug and grease, then plug in end cover.

If we can assist further with this unit, call us at 662-871-8403

tupelohydraulics@gmail.com