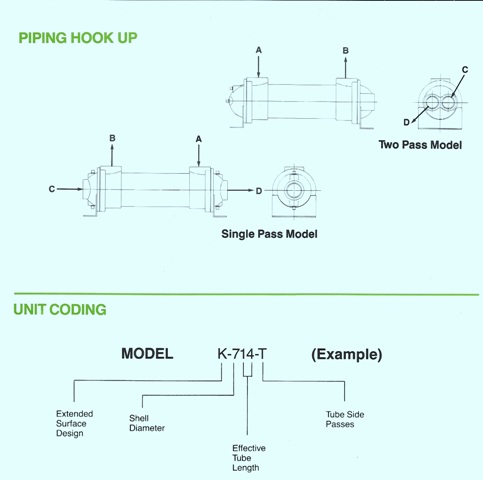

To hookup fluid that is hot in the lines and the water that is cooled in the lines you will need an automatic water regulating valve. You will need to put in inlet end of the cooler. Then put the water outlet piping in such a way that the exchanger stays submerged with water and with little pressure. If you happen to have a leak and you don’t do this, water will go inside the oil chamber due to fluid pressure that may occur. You will need to put the temp probe is put in the reservoir so it can tell if the system temps go up or down. There is generally no perimeters on how the coolers are put on. You may have to look and see how the water may need to drain on either the water or oil after you put the cooler on. To keep your lines from getting hot fluid efflux you may need a relief valve put in the inlet line of the cooler. If you have your water coming from other places, you may want to put in a strainer of some type to keep out debris, so it don’t get into your cooler.

If you need questions answered or in need of a repair, call us at 662-871-8403

tupelohydraulics@gmail.com