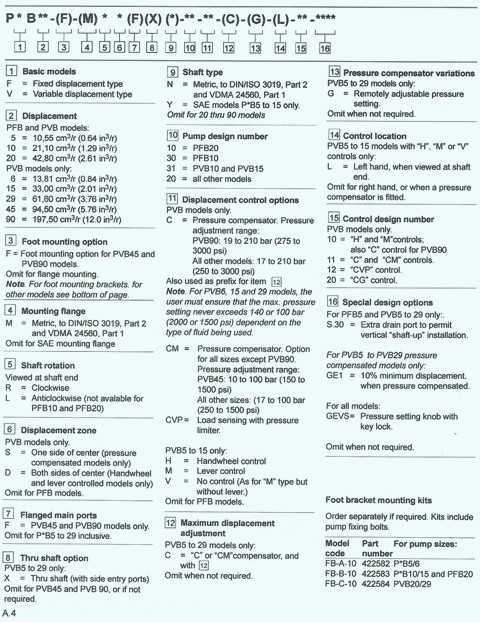

Look on the model code for control data information each model.

C and CM Pressure Compensators

This means it will intuitively change how the pump will handle pressure at a predetermined time and amount of pressure at the time it is needed. The amount of pressure can go up or down (60 – 90 psi) within a standard cycle of circuit volumes. If you have a PVB6, 15 or 29 that has the code C on it, make sure the highest amount of pressure that you set doesn’t go over 2000 or 1500 psi. This will be determined by the kind of fluid you use. You can set this at 3000 psi if need be.

You should go by suggestions if you have a positive pump or relief valve needs to be mounted outside to help with overloading.

CC and CMC Pressure Compensators that have Adjustable Displacement Stop

On the pressure compensator part, works like it does in the above description. But on the adjustable displacement stop part lets the highest amount go to the pump so it can be adjusted to the percentage you need for that job. When you need to prime it, set it where it will let 40% of the highest displacement to be needed.

CG Pressure Compensator that is Remotely Controlled

As for the C, it is the same description in the first paragraph and with this CG code it is already determined remote pressure that is appropriate for pilot controls. You can adjust the remote controls on the pilot relief or pilot directional valves in any series or parallel in a system. You can asked to shown how to remotely adjust controls.

CV Load Sensing Compensator Remote Controlled

It will adjust itself remotely to give the pump in the system the right amount of pressure (250 psi) above the load pressure. The extra pressure needed maybe caused by a compensator that doesn’t have a flow control or the spool could be opening on a directional control valve.

Either way can be adapted for a fixed or variable speed pump drive. If it is the spool opening the fixed restrictor will give off a predetermined and steady flow that is of it’s on accord on drive speed. Making sure the speed don’t go over that gives the needed flow at the entire displacement. You will need an external pressure limiter to be put on to help with the overloading on the pump. The syncing of pump pressure and portage to the system that it includes power matching and syncing up by eliminating power depletion.

H Handwheel Control

This just means you can manually control and determine how pressure flows and when. You can control it on either side, by means of bi-directional flow settings. If you hand turn it, then here is the displacement per turn:

PVB5……………… .16 in. PVB6……………… .21 in PVB10……………. .32 in PVB15……………. .5 in

M Lever Control

You can do remote or manual controls. You can work it from either side of the center if it is bi-directional flow is permitted in the settings. If you have a pintle mount lever control you will need to make sure it is securely put on a linkage to give the best settings for it. The pintle navigation is restricted by internal stops to 17.5 inches from the center.

Controlled torque…….(torque changes with pressure and speed)

PVB5…………………………… 3.8 nm at 33 lb per ft at 3000 psi PVB6………………………….. 2.7 nm at 24 lb per ft at 2000 psi PVB10/15…………………… 7.5 nm at 66 lb per ft at 1000 psi

GE1 Least amount of Displacement Control

There are choices for C(M)(C) & CG(C) compensators control the displacement in full compensated mode to slightly 10% of full displacement.

Hydraulic Fluids

It is best to use anti wear hydraulic oils, water glycols and water in oil mixtures. You might be able to use water base fluids if pressures go up to 1000 psi. But ask a mechanic about that first. Your most intense operating thickness goes from 220 to 13 cst for all the pumps( the exceptions to this is 5%/95% mixture is used. They suggest running it at 54 to 13 cst.

If more info is needed for this type of controls, call us at 662-871-8403

tupelohydraulics@gmail.com